Classification and selection of board-to-board connectors

1. What is a board-to-board connector?

The basic concept of a board-to-board connector is to connect different circuit boards together. It is the connector product with the strongest transmission capacity among all connector product types. It is mainly used in power systems, communication networks, financial manufacturing, Elevators, industrial automation, medical equipment, office equipment, home appliances, military manufacturing, and other industries.

At present, the main pitches of board-to-board connectors are 0.50mm, 0.60mm, 0.80mm, 1.00mm, 1.25mm, 1.50mm, 2.00mm, 2.50mm, 2.54mm, 3.96mm

2. Classification and characteristics of board-to-board connectors

Board-to-board connectors are divided into different types according to the different connection methods between the circuit boards. Each type has its own characteristics. The following is an introduction to this aspect for you one by one:

First, pin header/pin header

Pin headers and female headers, also called power strips, are the cheapest and most common connection methods.

Application scenarios: low-end, large-size smart devices, development boards, debugging boards, etc.

Advantages: cheap and convenient, the hard connection is very stable, strong over-current capability, convenient for wire bonding and testing.

Disadvantages: Large size, difficult to bend, large spacing, difficult to connect hundreds of pins (too large).

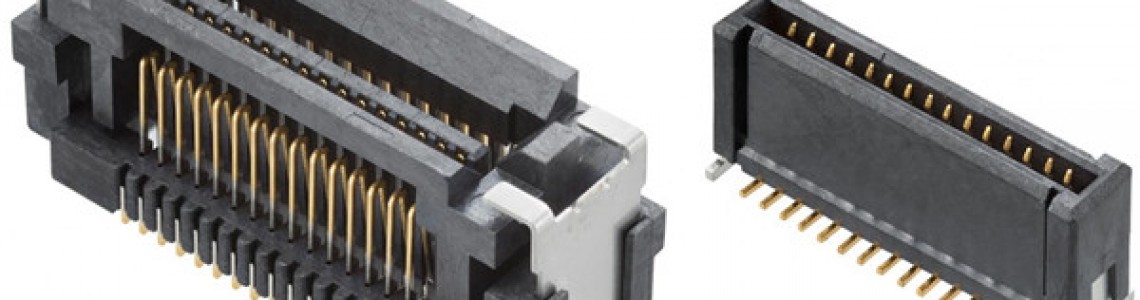

Second, some high-end board-to-board power strips

It is denser than the pin header and is used a lot in compact products.

Application scenarios: Basically all conventional smart hardware products are in use, and they are widely used.

Advantages: a large number of pins, small size, 1 cm length can do 40 feet (the same size of power strip can only do less than 20).

Disadvantages: expensive, can not be plugged in and out frequently, and the structure design needs to be fixed.

Third, thickened board-to-board connector

Board-to-board, board-to-wire, can be disassembled, combined, and can be inserted into the header.

Use scenarios: development boards, test boards, large and fixed devices (such as computer case wiring)

Advantages: cheap, common, used with pin headers, very easy to connect and measure

Disadvantages: large size, not easy to fix, not suitable for mass production scenarios.

Fourth, FPC connector plug/ZIF connector

Many smart hardware devices need to pull out the signal from the motherboard. FPCs are flexible, small in size, and changeable in shape, making them the best choice.

Usage scenarios: the connection of the mainboard and the auxiliary board, the connection of the mainboard and the peripherals, the need to bend the circuit, and the compact product space.

Advantages: compact and cheap.

3. Who are the board-to-board connector manufacturers?

At present, the world's top board-to-board connector manufacturers mainly include Tyco Electronics, Molex, Joint Tech, Amphenol, FCI, and JAE. As for the sales model of Joint Tech (HR Chanda), it is mainly sold by domestic agents in mainland China. At present, their agents in mainland China are mainly Jianya Electronics.

4. How to select the board-to-board connector?

It is very important for users to purchase board-to-board connector products correctly. So, how to choose a board-to-board connector, and what are the selection criteria?

In recent years, the board-to-board connector is moving towards a smaller trend. The most common board-to-board connector pitch for handheld consumer electronic devices is 0.40 mm; while the stack height of 1.00 mm is a small connector, the connectors currently used by major original equipment manufacturers are as low as 0.70 mm, and sometimes even lower. Old-fashioned miniature connectors with a width of more than 4.00 mm a few years ago were replaced by connectors with a width of 3.40 mm. The current "narrow-body" board-to-board concept is usually in the range of 2.40 to 2.60 mm. Board-to-board products, is the smaller the better? When purchasing board-to-board connectors, in addition to basic issues such as circuit size, stack height, and width, several things need to be considered:

Is it true that the smaller the better? If you are willing to accept a smaller vacuum port pickup area, then maybe you are right. Before choosing a subminiature connector, you must check whether the connector has all the other properties you need, and carefully test it to ensure that it is strong and durable.

Then, it seems necessary to choose a socket with a top-mounted connector, because this setup can run tracking under the socket and is likely to facilitate the use of conformal paint. Some disadvantages of top-mounted sockets are that the width of the vacuum pick-up area is often narrow. There is no plastic shell material above the socket terminals to prevent the rise caused by rough disconnection. The more uneven top surface of the socket may be a connection work belt for the operator Come trouble.

These new connectors with greater disconnection sound great! Yes, but you may need to tolerate additional connector lengths in order to achieve the locking function required by these connectors; greater disconnection force usually also means greater engagement force, which may also be a larger size circuit Bring problems.

After reading the above, you should understand board-to-board connectors. For more articles related to board-to-board connectors, we will continue to organize and publish on the blog of the website. Interested users should remember to pay attention to our latest updates. dynamic

Leave a Comment